Hydrogen and Oxygen Production Equipment

We currently provide a wide range of hydrogen and Oxygen production equipment, from 0.2Nm3/hour to 1500Nm3/hour, with 1.6Mpa/3.2Mpa working pressure. Our gas purity could reach 99.9% and after enhanced processing, it could reach 99.999%.

Our production offers a consolidated solution, including electrolyzer, gas-liquid separation frame (hydrogen purification frame, oxygen purification frame), rectifier cabinet & control cabinet, Transformer and auxiliary system. We aim to provide a turn-key solution with training and maintenance locally and timely.

Case for the containerized hydrogen production equipment

The containerized hydrogen production set are convenient for installation, and the on-site installation workload is small. With highly integration, the equipment components are installed in a fixed limited space, by using limited space for a reasonable arrangement, so that the equipment covers a small area. It is easy to move, and flexible for transportation. Considering the quick construction of a hydrogen station, it saves the investment in building a hydrogen station and also simplifies the approval procedures.

Currently, a single set of containerised hydrogen production equipment can reach a maximum capacity of 200m3 per hour.

Consite installation: 10 days

Size: 20ft/40ft container

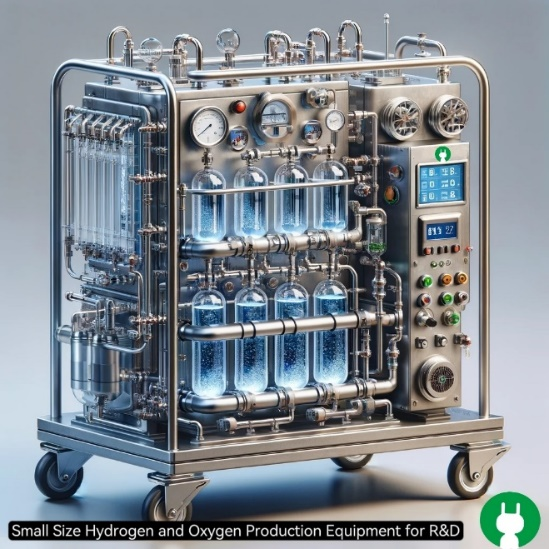

Laboratory Hydrogen Production Equipment

Hydrogen energy is considered the most promising clean energy of the 21st century and has been widely researched by countries around the world since the 1970s.

Our company has tailor-made modular alkaline electrolytic water hydrogen production test platform for universities and academician team, with minimum 0.2m3/hour hydrogen production capability and >99.80% purity.

Case for Top 3 Universities in China for Hydrogen Research

It is mainly used to study the mechanism of hydrogen production from alkaline electrolytic water (including catalyst, diaphragm and electrolyzer structure), to improve the performance of alkaline electrolytic water hydrogen production system, and to study the coupling mechanism between alkaline electrolytic water hydrogen production system and renewable energy system, such as wind and light, in order to realize large-scale electrolytic hydrogen production from renewable energy.

Technical Parameters of Hydrogen Production System

– Design pressure: atmospheric pressure / with pressure (slightly positive pressure)

– Working temperature: 90±5℃.

– Hydrogen output: 220L/hour

– Oxygen output: 110L/hour

– Outlet hydrogen purity: 99.8% 6.

– Outlet oxygen purity: 98.5 per cent

– Working medium: 30% KOH

– Electrode mesh: pure nickel mesh, can be coated with catalyst by itself.

– Volume: 2000mmX1500mmX2100mm

– Weight: 500kg

Green Hydrogen Ammonia Integrated Manufacturing Site

Green ammonia is produced from green hydrogen, which can be diluted and used as a liquid ammonia fertilizer to replace traditional nitrogen fertilizers such as urea, allowing agriculture to reduce greenhouse gas emissions throughout the production cycle, thus mitigating the effects of global warming. Green liquid ammonia fertiliser can be diluted and used for watering, spraying or added directly to the irrigation system for easier and quicker

absorption and results. Our hydrogen to ammonia plant is designed for overseas farms and fertiliser plants, which is easy to transport, easy to install, safe and reliable.

Case for Agri Solar+Hydrogen+Ammonia Park

The project consists of PV green electricity plant and hydrogen production. Green hydrogen is used by the local chemical plant as a substitute for coal, which reduces the use of coal per year and cuts CO2 emissions. Due to the very low rainfall in the area, drip irrigation is used throughout the plantation, which has resulted in improved crop yields through the direct release of diluted green liquid ammonia fertiliser produced from green hydrogen.

Basic data of 3000 ton Ammonia Plant:

– Area: 0.7 hectare

– Production Capability: 3000 ton per year

– Water consumption: 4 ton per year

Hydrogen Refueling Station Integrated Hydrogen Production and Refueling Station

To reduce cost of hydrogen transportation and ensure the hydrogen supply security, on-site hydrogen refueling station is designed. On-site hydrogen generator could be from methanol reforming, SMR, or electrolysis of renewable electricity.

According to the resources of raw materials for hydrogen production at the site of the hydrogen refueling station, hydrogen which meets the requirement of PEM fuel cells could be produced on-site. The product hydrogen is compressed to 20MPa for primary storage, and then pressurized to 45MPa or 90MPa, and then filled into fuel cell vehicles through the hydrogenation machine.

The on-site hydrogen refueling station is especially suitable for heavy trucks, logistics vehicles in logistics parks and special tourist lines.

Pressure:

Chlorine production outlet pressure: 2.0Mpag

Hydrogen storage pressure: 20MPa or 45Mpag

Filling Pressure: 35 or 70 Mpag

Case for Winter Olympic Game

It is an international demonstration project for the generation, storage and use of a hydrogen system with wind-solar coupling at MW level.

System Features

Container skid design, high integration and small footprint.

Unified intelligent control system with high degree of automation.

Large operating flexibility, hydrogen production can be standby.

It is easy to expand the existing natural gas filling station.